Analysis of the causes of slope safety accidents

Slope safety management is the top priority of open-pit mine safety. Slope accidents account for a large proportion of open-pit mine accidents. There are three types of slope accidents, such as collapse of rock mass, sliding of rock mass and falling of suspended rock. many. In addition, in the event of collapse and rock mass fall, serious casualties may result. The main reasons for the instability of the slope are:

1. The mining method is not correct, such as the bottom mining, the explosive amount is too large when blasting.

2. The composition of the slope is unreasonable, such as the stage height, the stage slope angle, and the final slope angle, which are inconsistent with the relevant regulations and design requirements.

3. The geological structure has not been ascertained, such as joints, fissures, bedding, faults and fracture zones, as well as the distribution of weak layers, extension length and degree of intersection formed by unstable soft rock interlayers and soft rock surfaces experiencing water expansion.

4. The physical and mechanical properties of the rock have not been investigated.

Preventive measures

1. Adhere to the top-down, step-type mining method. The height of the step must be controlled to about 10m, and the angle of the step slope must be controlled within 70°. Persist in the vertical blasthole, it is strictly forbidden to carry out the bottom boring at the bottom of the working steps to prevent the formation of overhanging rocks, umbrellas or hollows.

2. The drainage ditch must be excavated at the top of the slope to prevent the surface water from directly rushing to the slope of the stope. If there is water seepage in the slope, drainage and drainage measures should be taken.

3. Due to the earthquake generated by the blasting operation, the joints of the rock mass can be opened. Therefore, large-scale blasting should be avoided as far as possible in the slope area, and controlled blasting techniques such as millisecond blasting, pre-splitting blasting and shock blasting can be adopted. And strictly control the amount of explosives simultaneously blasted. In the stope, try not to throw blasting, loose blasting should be used to prevent flying stones from injuring people and reducing damage to the slope.

4. Before the operation of the operator and during the operation and after each blasting, the slope surface should be inspected for safety. If there is a crack on the working surface or there is pumice on the slope, the dangerous stone and the umbrella body may collapse, the relevant personnel should immediately evacuate. Take safe and secure precautions in a safe place.

5. Management measures

(1) Establish a safety inspection system for slopes.

(2) Clearly experienced personnel are responsible for the safety management of slopes.

(3) Eliminate hidden dangers in time and find that cracks, pumice stones, suspended rocks, umbrellas, etc. on the slope must be dealt with promptly.

(4) Check and remove pumice in time after the end of each blasting operation.

(5) When it is found that a major accident cannot be dealt with, it must be reported to the relevant department at a higher level.

(6) Set up special personnel to inspect the key landslide area, record, and set up observation points in the geodetic department to observe changes in horizontal and vertical displacement.

|

Part name

|

Material

|

|

SDA oxidized aluminum tube

|

hard anodized aluminum alloy

|

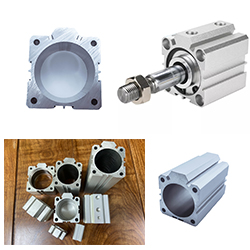

Compact Pneumatic Cylinder SDA

SDA Compac Aar Cyinderis caled ufre-hn c nde ease fis strucre The comact nemac cnder tok and er cower s and os ddod meo stutre makes he tnder camnatand ete.Air Cylinder Tube.

Bore Sizes:12.16,20.25,32.40.50.63,80.100mm

Stroke Lengths: 5.1015.20.25,30.40.5075.100.130mm

Operating Pressure: 0.2-0.9MPa Single action; 0.1-0.9MPa Double action

Speed: Double action:30-500mm/s Single action:50-500mm/s

Working Environment Temperature: -10 to 80%C

The SDA series cylinder is a thin cylinder produced by brands such as Airtac. This type of cylinder is widely used in the field of industrial automation due to its compact design and efficient performance. Here are some key features and advantages of SDA cylinders:

The main features of SDA cylinder are:

Thin design: The SDA cylinder has a relatively thin external dimension, making it particularly suitable for applications with limited space.

Lightweight: Due to its lightweight design, it is easy to install and operate.

Embedded installation: This type of cylinder can be installed in an embedded manner, which helps save space and simplify the installation process.

Easy to maintain: The design of SDA cylinders makes maintenance simple and convenient.

Stability of operation: Smooth expansion and contraction during operation, less prone to jamming.

Efficient installation: It can be directly installed on the device to improve installation efficiency.

Effective travel: It has a long effective travel and is suitable for various application needs.

Multi functional installation: The cylinder surface has multiple magnetic switch installation points, which can be installed in any direction.

Durable and sturdy: The piston rod is designed to be stable and prevent dangerous ejection, while the cylinder is specially treated internally to reduce friction and increase service life.

Impact resistance and corrosion resistance: The cylinder has high strength and good impact resistance, and can maintain good sealing and corrosion resistance after long-term use.

Temperature resistance: able to withstand high temperature environments (about 120 ° C), with good temperature resistance and aging resistance.

Application areas:

Automation equipment: such as assembly lines, packaging machinery, etc.

Textile machinery: used for various textile processing equipment.

SDA Pneumatic Cylinder Barrel,SDA Pneumatic Cylinder Tube,SDA Pneumatic Cylinder Tubing,SDA Pneumatic Cylinder Pipe

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com