"China Made 2025" has been published for nearly a year. The conceptual level can be described as colorful. From industrial 4.0, industrial informatization to smart manufacturing and unmanned factories, it now extends to driverless cars, unmanned ships and unmanned medical equipment. In other hot areas, it seems that the era of industrial intelligence and unmanned people is close at hand.

Ren Zhengfei, the founder of Huawei Technologies, is very objective in his judgment. He believes that this is an era of artificial intelligence. First, it must emphasize industrial automation; after industrial automation, it will be possible to enter informationization; only after informationization can intelligence be realized. Chinese industry has not yet completed automation, and many industrial companies cannot even achieve semi-automation.

Therefore, before exploring Industry 4.0 and industrial uninitiated, it is necessary to understand the historical origins, technical origins, and economic significance of related concepts.

Automation is the prelude to intelligence

In the 1980s, the American auto industry was worried that it would be shot down by Japanese competitors. In Detroit, many people are looking to beat their opponents with "light out production." "Light extinguishing production" means that the factory is highly automated and the lights are turned off, and the robots themselves are making cars. At that time, this idea was impractical. The competitive advantage of Japan’s auto companies was not in automating production, but in “lean manufacturing†technology. Lean production in most cases depends on manpower.

Nowadays, advances in automation technology have made “light-out production†a reality. Japanese robot manufacturer FANUC has been able to put some of its production lines in an unattended environment and run autonomously for weeks.

German Volkswagen aims to dominate the world, this auto industry group has developed a new production strategy: modular transverse moment. Volkswagen wanted to use this new process to produce all models on the same production line. This process will eventually enable the masses to adjust their locations in factories around the world and produce any models needed in the local market.

Many years ago, Qian Xuesen once said: "As long as the automatic control is done, even if the components are a little inferior, the missile can hit the sky."

Today, automation will largely mimic human intelligence. Robots have been used in industrial production, marine development, and space exploration. Expert systems have achieved remarkable results in medical diagnostics and geological exploration. Factory automation, office automation, home automation and agricultural automation will become important contents of the new technology revolution and will be rapidly developed.

As a whole, China's traditional industries still have a large gap in terms of technology and equipment, energy and raw material consumption, product quality, and management level compared with industrial powers. In particular, the gap in technical equipment (such as high-end CNC machine tools) has expanded. . Large-scale equipment upgrades cannot be sustained by the state; maintaining the status quo of equipment will lead to disastrous consequences. Only by applying automation technology to transform traditional industries can the company's quality be improved most effectively.

Vitrans Automated Production Line Pallet Conveyor System

Professional customized production line Conveyor and assembly line conveyor, automated, modular, make your production and andassembly more efficient and upgrade your production line easier. No matter what the product is, it will increase your production line capacity.

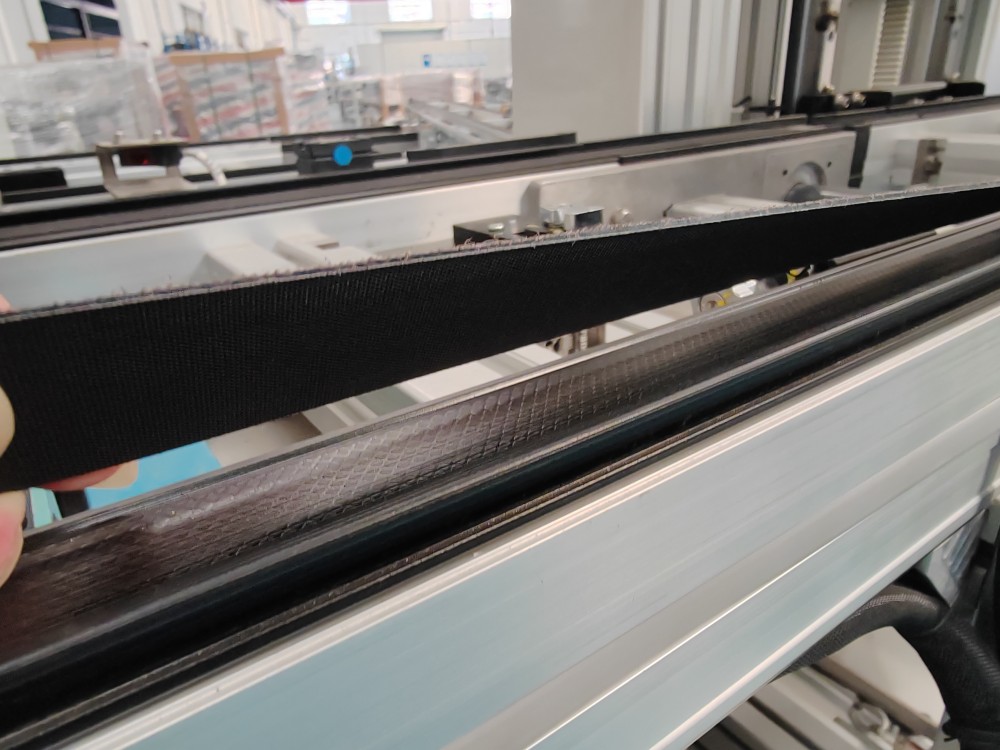

Vitrans Flat Belt Conveyor: Precision Handling for Efficient Production Lines

Key Features:

Modular Design:

Vitrans Flat Belt Conveyor boasts a modular design, providing flexibility and scalability to adapt to the evolving needs of your production line.

ESD Compliance:

Ensure the safety of sensitive electronic components with our Electrostatic Discharge (ESD) compliant flat belt conveyor, minimizing the risk of damage in high-tech environments.

Extended Lengths:

Gain a competitive edge with conveyor lengths that can be built up to 18 meters. This extended reach not only enhances efficiency but significantly lowers overall costs.

Precision Positioning:

Experience unparalleled precision with a positioning accuracy of ±0.05mm, ensuring consistent and reliable handling of your products.

Advantages:

Cost-Efficiency:

Vitrans stands out by providing extended conveyor lengths of up to 18 meters without compromising on cost-effectiveness. Maximize your efficiency without breaking the bank.

Versatility in Design:

Tailor your pallet handling system with Vitrans' flat belt conveyor's versatile modular design, allowing customization for diverse applications and industries.

ESD Protection:

Safeguard your electronic components with our ESD-compliant conveyor, ensuring the integrity of your sensitive products throughout the handling process.

Competitive Pricing:

When comparing Vitrans to competitors such as Bosch, Dorner, and Flexlink, our commitment to offering competitive prices ensures you get superior quality without the premium cost.

Choose Vitrans for a flat belt conveyor that goes beyond industry standards, providing a foundation for streamlined and cost-efficient automation in your production line. Optimize your processes with precision, reliability, and innovation-choose Vitrans for your industrial conveyor needs.

Belt conveyor,Pallet Conveyor,Modular Conveyor,Pallet Transfer Conveyor,Pallet Handling System Solutions,Vitrans Automated Production Line Pallet Conveyor System

Vitrans Automation Equipment Co.,Ltd , https://www.vitrans-conveyor.com